Confectionary company in North Macedonia saves energy and improves product quality

Investor

Evropa AD

Location

Skopje, North Macedonia

Investment

Replacement of a boiler, rehabilitation of a steam system, modernization of two production lines

Investment Size

EUR 903,000

Energy savings

2,381 MWh per year

CO2 savings

490 tonnes per year

Impact

Decreased energy, water and raw material consumption, enhanced product quality, increased production

Donor

European Union, Western Balkans Investment Framework

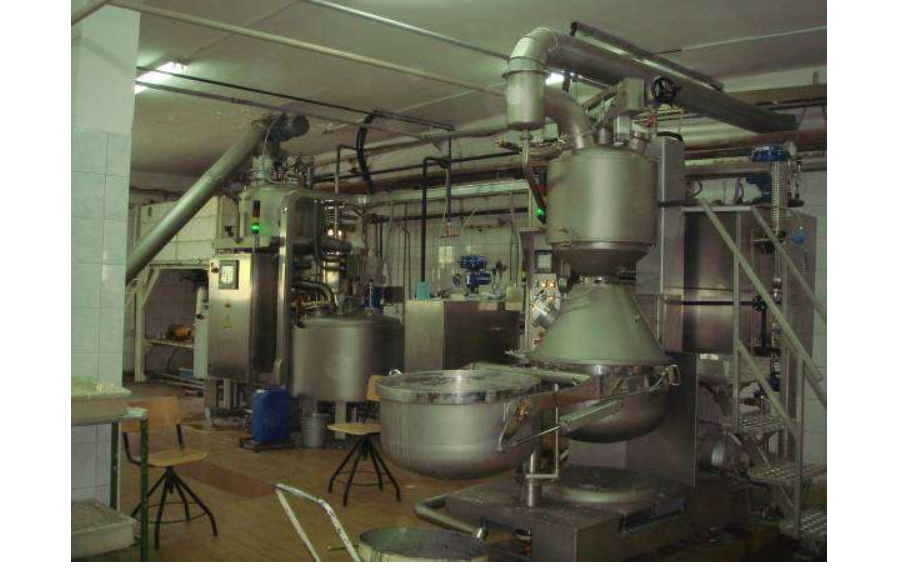

Confectionary producer upgrade its outdated technologies in order to save energy and money and improve its product quality.

Evropa AD was originally established in 1882, as a craftsman’s workshop for production of candy, Turkish delight (locum) and similar products made with sugar, with daily capacities of 250 kg and five employees on a 150 m2 working surface. Over the years it gradually expanded to the company which employs 430 workers and produces 5,000 tonnes of confectionary products. About one third of its production is sold on the domestic market and the remaining two thirds are sold on the foreign markets.

Since many of its current technologies were aging, resulting in high energy costs and raw materials losses in the production process, the Evropa’s management decided to invest in technologies of newest generation in order to save energy and money, but also to improve production process and quality of a final product. To be able to implement this investment project, Evropa approached Ohridska banka North Macedonia, a Partner Financial Institution of WeBSEFF. The WeBSEFF team assessed project savings and eligibility against the EBRD criteria.

To reduce its production costs, the company decided to invest in 1) replacement of its old and very inefficient boiler with a modern one that will achieve 95% efficiency, while the economizer will also reduce water consumption; 2) upgrade of their enrober production line to increase capacity and improve both efficiency of the tempering process and product quality using temperature controls; 3) replace the vacuum system of the lozenge production line to reduce raw material losses and enhance quality; and 4) rehabilitate the steam and condensate system.

The investment of EUR 903,157, out of which the WeBSEFF loan portion was EUR 770,000, provided energy savings of 31% and financial savings of EUR 262,200 which enabled simple payback of the investment in less than 3.6 years. Primary energy savings of 2,381 MWh were accomplished, as well as water savings of 4,100 tonnes per year and annual reduction of carbon dioxide emissions for 490 tonnes. The investment was supported with the WeBSEFF financial incentive of EUR 126,200.

The Western Balkans Sustainable Energy Financing Facility (WeBSEFF) was developed by the European Bank for Reconstruction and Development (EBRD) and is supported by the European Union and the Western Balkans Investment Framework (WBIF).